Description

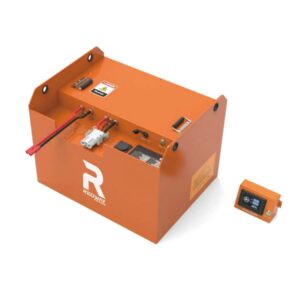

Our 48V 550Ah LiFePO4 Forklift Battery is a premium lithium battery solution engineered for heavy-duty industrial applications. As a trusted OEM lithium battery manufacturer, we deliver high-efficiency power systems that streamline material handling operations while minimizing lifecycle costs for global wholesale buyers.

Key Features

High-Density Energy Storage: 48V/550Ah configuration generates 26.64 kWh per charge cycle, supporting 18+ hours of continuous operation for Class I-III forklifts.

Extended Service Life: 4,000+ cycles at 80% DoD ensure 3x longer lifespan than conventional lead-acid batteries, with <3% annual capacity degradation.

Peak Performance Engineering: Sustains 500A continuous/800A pulse discharge for heavy lifting scenarios, backed by military-grade heat dissipation technology.

Rugged Environmental Protection: IP67-rated enclosure operates flawlessly in -4¡ãF~140¡ãF conditions, resistant to dust, humidity, and mechanical vibration.

Intelligent Power Control: Dual-channel BMS with RS485/CAN-bus integration enables fleet-wide SOC tracking and predictive maintenance alerts.

Product Description

This OEM-ready 48V 550Ah LiFePO4 Forklift Battery redefines industrial energy standards with its modular architecture (1100¡Á650¡Á750mm). Proprietary cell-stacking technology ensures uniform current distribution across 1520Wh/kg energy density cells, while the auto-balancing BMS maintains ¡À0.05V voltage tolerance. Customizable charge profiles (0.2C-1C) enable 4-hour fast charging without compromising cycle longevity.

As a lithium battery manufacturer specializing in OEM partnerships, we incorporate ISO 13849-compliant safety mechanisms: multi-stage overvoltage protection, isolated thermal runaway prevention, and short-circuit current limitation (<0.1ms response). The battery¡¯s CAN 2.0B protocol supports integration with Toyota/Hyster/Crown forklift telematics systems for real-time health monitoring.

How to Optimize 48V 550Ah Lithium Forklift Battery Performance

Maintain 20%-80% charge cycles using temperature-compensated chargers (41¡ãF-104¡ãF). Conduct monthly BMS firmware updates via CAN interface to enhance cell balancing accuracy by 15%.

Longevity Tips for 48V 550Ah Lithium Forklift Batteries

Store at 30% SOC in climate-controlled environments (59¡ãF¡À5¡ãF). Perform quarterly terminal torque checks (35-40 N¡¤m) to prevent resistance buildup.

Safety Protocols for 48V 550Ah Lithium Forklift Batteries

Utilize IP67-compliant connectors when operating in wet conditions. The dual-redundant BMS triggers emergency shutdown if internal pressure exceeds 15kPa or cell temperature surpasses 149¡ãF.

Comparison with Lead-Acid Alternatives

Our lithium battery reduces energy waste by 27% versus lead-acid models, delivering 92% round-trip efficiency. The 1,650-lb weight advantage enables 11% faster acceleration in 8,000-lb load scenarios.

OEM Customization Options

Available with UL1973/CE/UN38.3 certifications, including custom branding, terminal configurations, and CANbus message protocols. Choose from FOB/EXW/CIF logistics solutions with 15-day lead times.

How Does a 48V 300Ah Lithium Forklift Battery Boost Efficiency and Safety?

A 48V 300Ah lithium forklift battery delivers high energy capacity, rapid charging, and extended cycle life, significantly boosting forklift operational efficiency and reducing downtime. Its advanced safety features and smart battery management system ensure reliable, safe performance in demanding industrial environments, making it a superior alternative to traditional lead-acid batteries.

What are the technical specifications of a 48V 300Ah lithium forklift battery?

A typical 48V 300Ah lithium forklift battery operates at a nominal voltage of 51.2V with an energy capacity of approximately 15.36kWh. It supports continuous discharge currents around 300A and peak currents up to 600A for short bursts. Dimensions commonly range around 725 x 350 x 530 mm, with weights near 125 kg. The battery features a robust metal casing with IP40 to IP65 ratings and operates effectively within -20℃ to 60℃ temperature ranges.

How does a 48V 300Ah lithium forklift battery improve operational efficiency?

This battery enables longer forklift run times per charge and supports fast charging, often under two hours, minimizing downtime. Opportunity charging during breaks keeps forklifts operational without battery swaps. Its flat discharge curve ensures consistent power output, enhancing productivity across multiple shifts.

What advantages do lithium forklift batteries offer over traditional lead-acid batteries?

Lithium forklift batteries provide up to 4 times longer cycle life, faster charging, zero maintenance, and higher energy efficiency. They eliminate acid spills and reduce environmental hazards while enabling lighter battery weight and more compact designs, improving forklift maneuverability and reducing operational costs.

How long is the cycle life and expected lifespan of a 48V 300Ah lithium forklift battery?

These batteries typically offer over 3,000 to 4,000 full charge-discharge cycles at 70-80% depth of discharge, translating to 5 to 8 years of operational life depending on usage and maintenance.

What safety features and certifications ensure the reliability of this battery?

Equipped with advanced Battery Management Systems (BMS), these batteries monitor voltage, temperature, current, and state of charge to prevent overcharge, over-discharge, short circuits, and overheating. Certifications such as UN38.3, MSDS, UL1642, and IEC62619 confirm compliance with international safety and quality standards.

How does charging and discharging work for a 48V 300Ah lithium forklift battery?

The battery supports continuous charge currents up to 150A with standard charge currents around 50-100A. Discharge currents typically reach 300A continuous with peaks up to 600A for short durations. Fast charging and opportunity charging are supported without damaging battery health, optimizing forklift uptime.

What are the physical size and weight considerations for installation?

Typical dimensions are approximately 725 mm long, 350 mm wide, and 530 mm high, with weights around 125 kg. These compact, lightweight designs compared to lead-acid batteries facilitate easier installation and better forklift balance.

How does temperature affect the performance of a 48V 300Ah lithium forklift battery?

Lithium batteries maintain stable capacity in cold environments and support charging in temperatures as low as 0℃. However, extreme cold or heat can reduce performance and lifespan, so temperature-controlled charging and storage are recommended for optimal battery health.

How do you select the right 48V 300Ah lithium forklift battery for your forklift model?

Selection depends on forklift power requirements, shift length, and operational environment. Confirm voltage compatibility (typically 48V nominal), required capacity (300Ah suits medium to heavy-duty use), and physical dimensions to ensure fit. Consulting with Lithium-Battery-Manufacturer ensures tailored solutions for specific forklift models.

What maintenance practices maximize the lifespan of lithium forklift batteries?

Maintenance is minimal but critical: keep terminals clean, avoid deep discharges, monitor battery health via BMS, and store batteries partially charged in cool, dry conditions. Unlike lead-acid, no watering or equalizing is needed, reducing labor and risk.

How does a smart battery management system (BMS) enhance safety and performance?

A sophisticated BMS continuously monitors battery parameters, balancing cell voltages, preventing overcharge/discharge, and protecting against temperature extremes. It enables real-time data communication via RS485, CAN bus, or 4G, allowing remote monitoring and predictive maintenance, ensuring safety and prolonging battery life.

Battery Performance and Specification Comparison Chart

| Specification | Typical Value | Notes |

|---|---|---|

| Nominal Voltage | 51.2V | Standard for 48V lithium forklift batteries |

| Capacity | 300Ah | High capacity for extended runtime |

| Energy | ~15.36 kWh | Total stored energy |

| Continuous Discharge Current | 300A | Supports heavy-duty forklift operation |

| Peak Discharge Current | 600A (3 seconds) | For short bursts of power |

| Charge Current | 50-150A | Supports fast and opportunity charging |

| Dimensions (L x W x H) | ~725 x 350 x 530 mm | Compact size for easy installation |

| Weight | ~125 kg | Lightweight compared to lead-acid |

| Cycle Life | 3,000-4,000 cycles | Long lifespan with proper use |

Charging and Temperature Range Chart

| Parameter | Range | Notes |

|---|---|---|

| Operating Temperature | -20℃ to 60℃ | Wide range for industrial use |

| Optimal Charging Temp | 0℃ to 55℃ | Ensures battery longevity |

| Fast Charge Time | < 2 hours | Minimizes forklift downtime |

| Opportunity Charge Time | 15-30 minutes | Enables charging during breaks |