Description

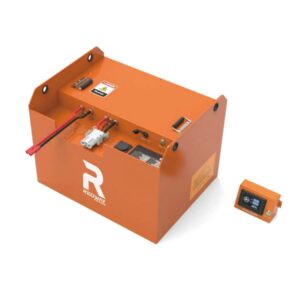

Our 24V 200Ah LiFePO4 Forklift Battery is a cutting-edge lithium energy solution engineered for industrial material handling. As a trusted lithium battery manufacturer, we specialize in delivering OEM-focused designs that combine durability, efficiency, and scalability to meet diverse operational demands.

Key Features

High Energy Output: 4.8 kWh capacity supports extended shifts, reducing downtime and boosting productivity in heavy-duty applications.

Robust Power Delivery: 200A continuous/400A peak discharge ensures consistent performance for lifting, stacking, and transporting heavy loads.

Unmatched Longevity: 5,000+ cycles at 80% DoD provide 3-5x longer lifespan than lead-acid alternatives, minimizing replacement costs.

Smart Safety Integration: Advanced BMS monitors voltage, temperature, and current in real time, preventing overcharge, short circuits, and thermal risks.

Extreme Environment Ready: IP67-rated housing and -20¡ãC to 60¡ãC operating range ensure reliability in warehouses, cold storage, and outdoor settings.

Product Description

Designed for seamless OEM integration, our 24V 200Ah LiFePO4 Forklift Battery combines compact dimensions (620¡Á440¡Á215mm) with a lightweight 50kg design to optimize forklift maneuverability. The modular LiFePO4 cells enable rapid 100A charging, achieving 80% capacity in 2 hours for uninterrupted shift operations. With military-grade cell balancing and a 5-year/5k-cycle warranty, this battery guarantees ROI certainty for wholesale and ODM partners. Customizable communication protocols (CAN/RS485) allow fleet operators to track SOC, health status, and energy consumption via IoT platforms.

Why Choose a 24V 200Ah Lithium Forklift Battery for Industrial Power?

A 24V 200Ah lithium forklift battery offers superior energy density, rapid charging, long cycle life, and lightweight design, making it ideal for demanding industrial forklift applications. It provides consistent power, reduces downtime with fast recharge, and lasts significantly longer than traditional lead-acid batteries, enhancing operational efficiency and lowering total cost of ownership.

What are the detailed specifications of a 24V 200Ah lithium forklift battery?

A typical 24V 200Ah lithium forklift battery has a nominal voltage of 25.6V and a capacity of 200Ah, delivering approximately 5120Wh of energy. It usually weighs between 39 to 88 kg (86 to 194 lbs) depending on cell type and casing. The battery supports continuous charge/discharge currents around 100A, with peak discharge currents up to 250A for short bursts. Internal resistance is low (≤10mΩ to ≤40mΩ), enabling efficient power delivery. It features a depth of discharge exceeding 100%, self-discharge less than 1.5% per month, and a cycle life typically over 3000 to 5000 cycles at 80% DoD.

Chart: Typical Specifications of a 24V 200Ah Lithium Forklift Battery

| Specification | Value |

|---|---|

| Nominal Voltage | 25.6 V |

| Capacity | 200 Ah |

| Energy Stored | 5120 Wh |

| Weight | 39 – 88 kg |

| Dimensions (L x W x H) | 520-620 x 270-440 x 210-220 mm |

| Max Continuous Discharge | 100 A |

| Max Peak Discharge | 250 A (15 sec) |

| Cycle Life | 3000 – 5000+ cycles |

| Self-Discharge | <1.5% per month |

How does the Battery Management System (BMS) ensure safety and optimize performance?

The built-in BMS continuously monitors voltage, current, temperature, and state of charge to prevent overcharge, over-discharge, short circuit, overcurrent, and thermal runaway. It balances cells to maintain uniform charge, extends battery life, and includes automatic fault recovery. Advanced models offer communication protocols such as RS485, CAN, or Bluetooth for remote monitoring and diagnostics, ensuring safe and efficient forklift operation.

What advantages do lithium forklift batteries provide over lead-acid batteries?

Lithium forklift batteries offer:

-

Faster charging times (1-2 hours vs. 8+ hours)

-

Longer cycle life (3000-5000+ cycles vs. 500-1000 cycles)

-

Reduced weight (up to 50% lighter), improving forklift maneuverability

-

Higher usable capacity with >80% depth of discharge

-

Lower maintenance with no watering or equalizing needed

-

Minimal self-discharge, enabling longer storage without degradation

-

Enhanced safety features with flame-retardant electrolytes and thermal fuses

These benefits lead to increased productivity, lower operational costs, and improved workplace safety.

What are the common applications for a 24V 200Ah lithium forklift battery?

These batteries are widely used in electric forklifts, pallet jacks, automated guided vehicles (AGVs), and other material handling equipment in warehouses, manufacturing plants, distribution centers, and ports. Their high power density and durability make them suitable for continuous heavy-duty industrial use.

How should a 24V 200Ah lithium forklift battery be charged and maintained?

Charging requires a compatible LiFePO4 charger with a constant current/constant voltage (CC/CV) profile, typically charging at 29.2V with current limits around 40-100A depending on battery specifications. Avoid charging below 0°C to prevent cell damage. Maintenance is minimal due to sealed construction and BMS protection but includes regular inspection of terminals, cleaning, and monitoring battery health via communication interfaces if available.

What is the expected lifespan and warranty for these batteries?

High-quality 24V 200Ah lithium forklift batteries typically last over 3000 to 5000 full cycles at 80% depth of discharge, translating to 5-8 years or more in typical industrial use. Warranties commonly range from 3 to 5 years, reflecting confidence in durability and performance.

How do temperature variations affect the performance of these batteries?

Lithium forklift batteries operate efficiently between -20°C to 60°C for discharge and 0°C to 45°C for charging. Capacity retention decreases at low temperatures but remains functional down to -20°C discharge. Many batteries include thermal management and safety cutoffs to prevent damage under extreme temperatures, ensuring reliable operation in diverse environments.

How can 24V 200Ah lithium forklift batteries be connected in series or parallel?

These batteries support modular configurations: connecting in series increases voltage for higher-power forklifts, while parallel connections increase capacity for extended runtime. Proper BMS and battery management are essential to balance cells and ensure safe operation in multi-battery setups.

How should one select the right charger for a 24V 200Ah lithium forklift battery?

Select a charger designed for LiFePO4 chemistry with CC/CV charging profiles, voltage limits around 29.2V, and current ratings matching the battery’s capacity (typically 40-100A). Chargers with temperature compensation and communication compatibility with the BMS optimize charging efficiency and safety.